CASE STUDY

Offsite Fabrication for working dairy

Key Activity

Client

Integral UK

Project

3.2mw cooling project

Year

2026

Key Activity

Client

Integral UK

Project

3.2mw cooling project

Year

2026

Details

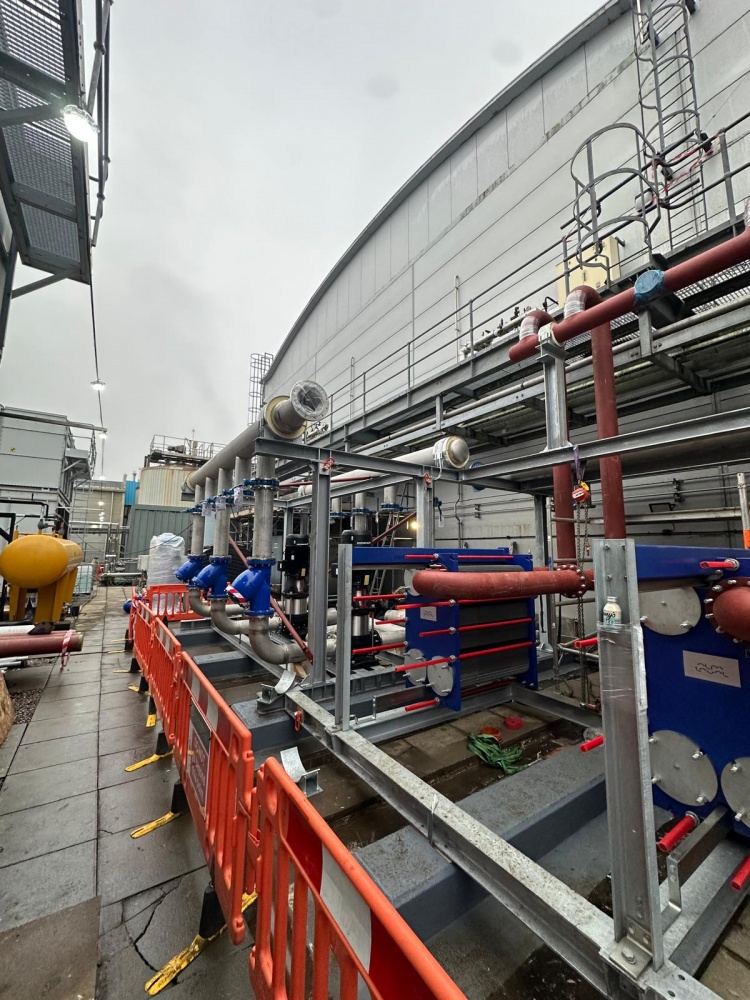

Large Skid unit off site fabricated and installed on site.

Our client Integral UK was asked in install 2 large skid units in on open roof space in the middle of a large production facility. Space was a premium and the site to remain working. We were asked to consider a way of off site fabricating 2 off skid units which consisted of a pump set glycol circuit plus a heat exchanger skid for the ammonia side. Because of existing services and limited space the design and fabrication of the units had to be exact, and significant consideration given to the interconnecting pipe runs. The constructability of the units had to not only consider the physical environment of where they were to be located but also transport and erection on site.

The overall cooling required was 3.2megawatt and the downtime on site was limited to 14 days.

It was agreed the units would be fabricated offsite, assembled, checked, tested, disassembled, loaded for transport, sent to site, lifted in a sequenced way to ensure minimal site down time and impact on traffic. A significant amount of thought and planning based on years of experience went into the project, including ensuring the steelwork was designed and calculated and understanding that the civils works may not fall within the 5mm tolerances. A pre install site survey confirmed some final adjustments would be required and the units were shipped to site.

Site install time was critical, our plan reduced site time by up to 3 weeks.

The final design was agreed with the client including the interconnecting pipework which was meticulously drawn out by Mark B and fabricated in our workshop in Hull. Both skids and all pipework was sent to site to be lifted into place using a 400 tonne crane and fit into the space provided which had no room for error due to the fact that this was a fully working site working 24-7 which meant that after the break ins which were carried out pre Christmas, the assembly of the 2 skids plus all of the interconnecting pipework on both the glycol and ammonia side was able to be installed within 14 days. It was noted that all the pre site time and final drawings and pre inspections of bases did add cost to the project but these costs far outweighed the loss to production time.

A project delivered hand in hand with our client, end user and builders, making use of EPS’s vast experience in this area, minimising risk and loss of production on site.

A great effort by the Integral team and our own Danny John and Mark bringing eyars of experience to this high risk isntall. A superb project to be involved with .